We’ve taken an in-depth look at three different metals so far: copper, iron and aluminium. We’ll be wrapping up our series, “Metal and Their Properties”, with a comprehensive look at one of the world’s most widely used metals: steel.

What is Steel?

Unlike the previous metals we have discussed, steel is not itself a chemical element. Rather, it is an alloy of carbon and iron, containing 1% manganese and other elements. Iron is the base element in steel, accounting for over 95% of the metal. The amount of carbon found in steel can vary, with low carbon steel containing 0.2%, and high carbon steel containing around 2.1% carbon.

Iron is usually found in the Earth’s crust in the form of an ore, typically iron oxide. Steel is often regarded as a ‘man-made’ metal, as the process of making steel involves removing impurities from iron.

History of Steel

Even though over 75% of modern steel has been made in the past three decades, the alloy has been around for a long time, with its history starting in the stars. Iron and carbon found their way into asteroids and eventually, Earth. Over time, people developed the know-how of melting iron into steel.

The Iron Age

In ancient Sumer, this alloy was called “an-bar”, which is translated to “metal from heaven”. At the time, the steel supply was extremely scarce, making this alloy more valuable than gold itself.

It took thousands of years for humans to begin looking under the earth for iron and, when they did find iron ore buried under their feet, the challenge became how to create iron from its ore.

It took 700 years to figure out this crucial step, but once the method was widely known, this marked the end of the Bronze Age, and subsequently, the beginning of the Iron age.

In around 400 BC, Indian metalworkers were the first to produce the world’s first true steel through a smelting method that bonded the perfect amount of iron to carbon. Iron bars were heated in crucibles, where the wrought iron melted and, after the furnace cooled, ingots of pure steel remained.

As the Roman empire fell, India continued to make its sensational steel but struggled to reliably ship the steel to Europe. In response, workers in Catalonia, Spain developed furnaces similar to those in India.

In the 19th century the Scottish immigrant, Andrew Carnegie, opened a steel mill in Homestead, Pennsylvania with the mission of building roads between cities and bridges over rivers. By the late 1800s, Carnegie was single-handedly producing half as much steel as the whole of Britain, and the country was soon steamrolling its way to the top of the steel industry.

The US continued to expand its steel production into the 20th century, producing 11.4 million tons of steel. WWI sparked increased production of steel in the States with orders coming from overseas, namely the UK.

While WWI dramatically expanded steel production, WWII well and truly revolutionised the manufacturing of the metal, with the US producing 25 times more steel than it did during the First World War.

In 1912, a British metallurgist named Harry Brearly experimented with chromium and steel alloys, finding that steel with a layer of chromium was resistant to weathering. This type of steel was soon termed as stainless steel and became a valuable commodity around the world.

The USA’s dominance of the steel industry ended in the 1970s due to lower wages overseas, and China soon replaced the US as the world’s largest steel producer by the 1990s. The East-Asian manufacturing giant remains today the top producer of steel.

What Are the Properties of Steel?

The properties of steel result from its chemical composition and method of manufacture. Due to its tensile strength, it is used in almost every industry. The following are some of the key properties of steel:

Formability – Steel is a metal that can go undergo plastic deformation without being damaged, making it a flexible metal for use in many different environments.

Durability – Since the 1800s, steel’s durability has been recognised as an upgrade to cast iron, largely due to its fire and wind resistance. The higher the concentration of carbon within the metal, the greater its durability.

Conductivity – Steel, particularly stainless steel, is a great conductor of heat, making it a good choice for domestic cookware.

Luster – This physical property of steel means it has an attractive outer appearance. Many steel products, therefore, often have a luminous outer surface.

Corrosion resistance – For a metal to be corrosion-resistant, it often needs to be alloyed with another metal. In the case of stainless steel, chromium is the key element added to derive this property.

Magnetic – Generally, steel is a magnetic material, but this depends on the type of steel in question. For example, steel cans are made up of ferromagnetic elements like iron and are attracted to magnets. However, austenitic stainless steel does not behave in a magnetic way due to its higher concentration of chromium and nickel.

Steel Alloys

As mentioned previously, steel is an alloy that can be combined with other metals. These include manganese, silicon, nickel, titanium, copper, chromium and aluminium. These elements are added to produce properties that are not found in regular carbon steel.

Differing percentages are used, resulting in the material having different properties, such as increased hardness or malleability.

For example, manganese improves resistance to shock and heat, whilst tungsten adds hardness and improves grain structure.

Alloy steel is generally much more practical than regular carbon steel which is one reason why it is commonly used in a variety of industries.

What is Steel Used For?

Steel’s economical cost and widespread availability means it is found in several industries and sectors, such as energy, construction and housing. In 2016 alone, over 1,600 million tonnes of steel were produced worldwide.

Steel has become a typical material used in building skyscrapers. It was first used for this purpose in 1884 to build the home insurance building in Chicago. The famous Eiffel Tower was also built using steel and, because steel and iron expand when heated, the tower is about 6 inches taller in summer than in winter. Thinking of a trip to Paris? Be sure to opt for July rather than January for a better view of the city at the top of the tower.

Here are just some examples of the many products made from steel:

- Baths

- Hardware tools

- Kitchenware

- Air conditioners

- Cans (Two-thirds of all canned goods’ packaging are made of steel)

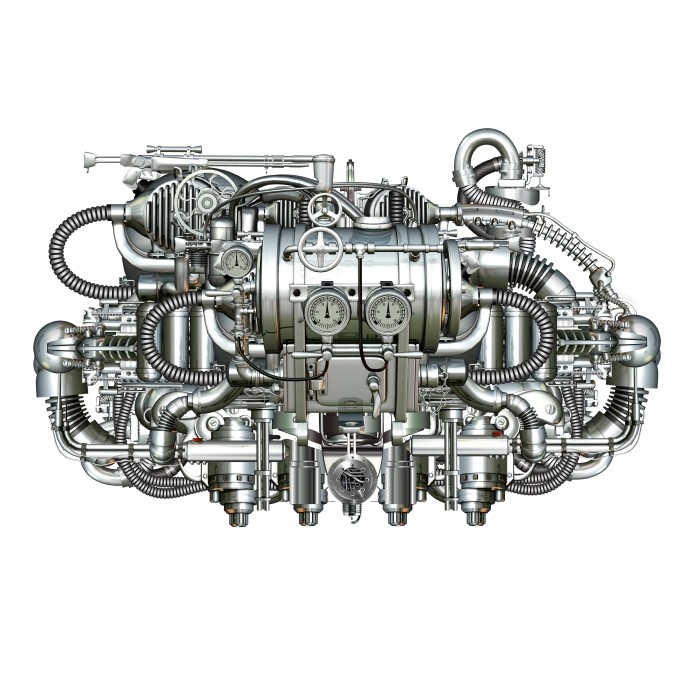

- Motor engines

- Tanks

- Trolleys

- Springs

- Boilers

As you’d expect, the list goes on and on due to steel’s incredible practicality.

Recycling Steel

Steel is a metal that is very easy and efficient to recycle, largely owing to its unique magnetic properties, as it can be easily recovered from the waste stream. Furthermore, the properties of steel remain unchanged during the recycling process; it never loses its compositional integrity regardless of how many times it is recycled.

The benefits of recycling steel are enormous as well. For example, recycling a single steel can save enough energy to power a 60-watt light bulb for almost 4 years.

Around 85% of steel at the end of its lifespan can be recycled, and 94% of steel in the UK is recycled when a building is demolished. This means that most steel products in use today contain a proportion of recycled steel; this helps to conserve resources and improve the carbon footprint of the steel industry.

Here at Morecambe Metals, we are happy to help with all of your recycling needs. Get in touch with us today to find out how we can help!